| POWERPOINT |

| PBO SERIES |

| PBO SERIES |

| PBO SERIES |

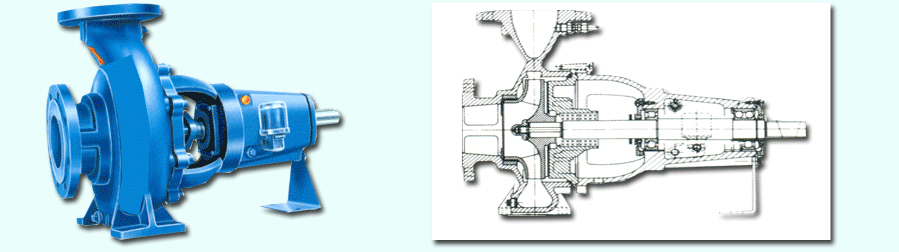

| End Suction Back Pullout Pumps |

APPLICATION :-

Type of Industries like chemical, textile, fertilizer, paper & pulp, petrochemical, food processing sugar, starch, refinery, powder plant, dairy, pharmaceutical and bulk drugs, oil extraction etc.

CASING :-

High efficiency volute type. Suction and discharge nozzle as well as the supporting feet are cast integral with the casing.

IMPELLER :-

Enclosed type and accurately balanced dynamically. Hydraulically balanced by back vanes and for large impellers by balancing holes.

SHAFT :-

Three shaft units cover complete range of pumps. Made of high tensil steel and accurately grinded all over.

STUFFING BOX :-

Available with suitable gland packing. Mechanical seal arrangement available upon request.

MATERIAL OF CONSTRUCTION :-

IMPELLER :- Cast Iron /SS-316, Cast Steel/Bronze etc.

PUMP CASING :- Cast Iron/SS-316, Cast Steel/Bronze etc.

SHAFT :- SS-410/SS-316-304

SEALING :- Mechanical Seal/Gland Packing.

RANGE :-

Capacity :- up to 400M³/Hr

Head :- up to 100 Mt

Temparature :- up to 350° C

Type of Industries like chemical, textile, fertilizer, paper & pulp, petrochemical, food processing sugar, starch, refinery, powder plant, dairy, pharmaceutical and bulk drugs, oil extraction etc.

CASING :-

High efficiency volute type. Suction and discharge nozzle as well as the supporting feet are cast integral with the casing.

IMPELLER :-

Enclosed type and accurately balanced dynamically. Hydraulically balanced by back vanes and for large impellers by balancing holes.

SHAFT :-

Three shaft units cover complete range of pumps. Made of high tensil steel and accurately grinded all over.

STUFFING BOX :-

Available with suitable gland packing. Mechanical seal arrangement available upon request.

MATERIAL OF CONSTRUCTION :-

IMPELLER :- Cast Iron /SS-316, Cast Steel/Bronze etc.

PUMP CASING :- Cast Iron/SS-316, Cast Steel/Bronze etc.

SHAFT :- SS-410/SS-316-304

SEALING :- Mechanical Seal/Gland Packing.

RANGE :-

Capacity :- up to 400M³/Hr

Head :- up to 100 Mt

Temparature :- up to 350° C

1 |

Pump Casing (CI/SS-304/316/Bronze)

|

8 |

Breath Valve (Optional)

|

15 |

Shaft (EN 8/SS 304/316)

|

2 |

Impeller (CI/SS-304/

316/Bronze) |

9 |

Double Row Thrust

Bearing (Optional) |

16 |

Bearing Bracket

(CI) |

3 |

Impeller Key (EN

8/ SS) |

10 |

Thrust Bearing Cover

(CI) |

17 |

Oil Seal (Optional)

|

4 |

Casing Joint (CI/SS)

|

11 |

Coupling Key (EN

8) |

18 |

Stuffing Box Cover

(CI/SS) |

5 |

Mechanical Seal

(Gland Packing) |

12 |

Oil Seal (Optional)

|

19 |

Back Wear Ring (Optional)

|

6 |

Line Bearing Cover

(CI) |

13 |

Bearing Locknut

(Steel) |

20 |

Impeller Nut (MS/SS)

|

7 |

Line Bearing (Steel)

|

14 |

Bearing Bracket

Foot (CI/MS) |

21 |

Front Wear Ring

(Optional) (CI/SS) |

|

|

|